Discover how innovative plunger technology is revolutionizing rod pump operations and improving bottom-line performance.

The Key to Oilfield Success: Efficiency

In the oil and gas industry, efficiency is the key to maximizing returns and maintaining a competitive edge. Yet, operators often encounter a series of hurdles that can hinder productivity—chief among them is the challenge of maintaining rod pump wells in abrasive environments. Frequent well pulls, pump failures, and excessive downtime can significantly impact profitability.

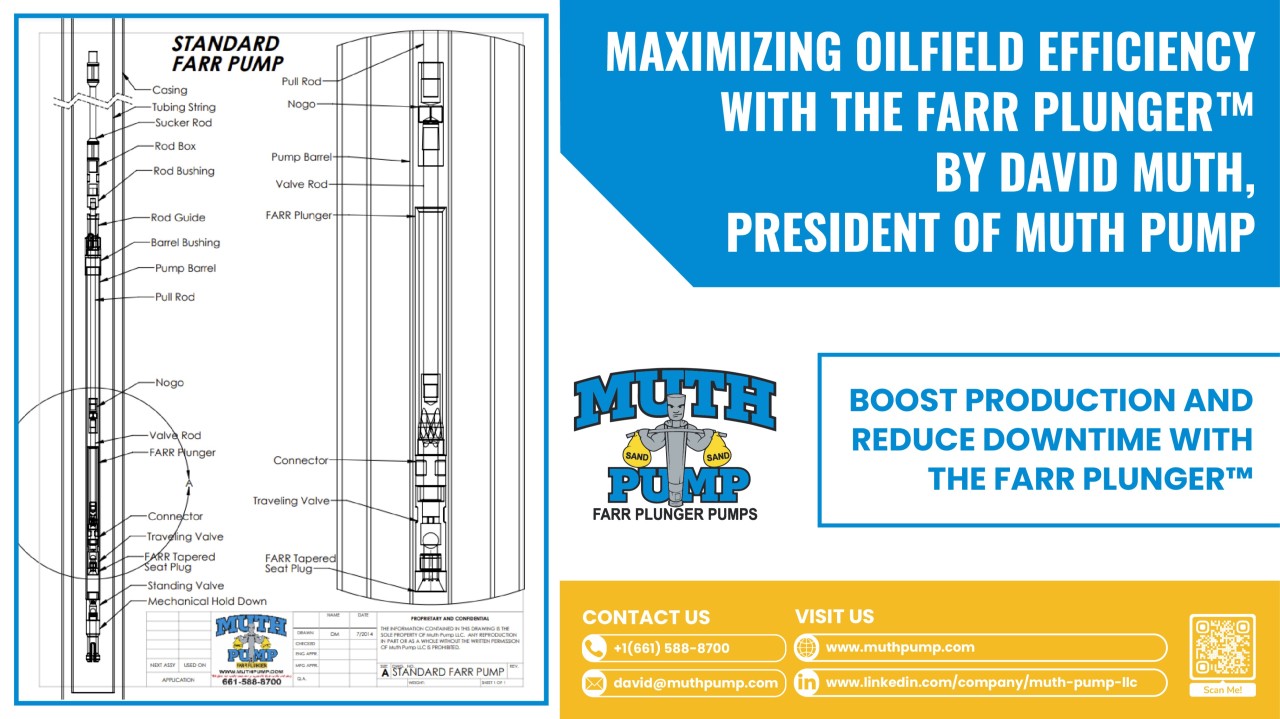

At Muth Pump, we’ve made it our mission to tackle these challenges head-on. One of our most innovative solutions is the FARR Plunger™. This advanced plunger is engineered to withstand the harshest well conditions, offering unmatched durability and efficiency that significantly extends pump life. Let’s take a deep dive into what makes this technology a game-changer for rod pump operations.

The FARR Plunger™: A Technical Breakdown

1. Advanced Material Composition

The FARR Plunger™ is constructed using high-grade materials specifically chosen for their resistance to wear and abrasion. Unlike traditional plungers, which are prone to rapid deterioration in sandy or high-solids environments, the FARR Plunger™ maintains its structural integrity, ensuring consistent performance over an extended lifecycle.

2. Unique Sand Tolerance Design

One of the standout features of the FARR Plunger™ is its ability to operate efficiently in wells with high sand content. Sand is a notorious enemy of pump equipment, often leading to premature failure and frequent maintenance. The FARR Plunger™ incorporates a design that allows sand to pass through more effectively, minimizing wear and preventing the kind of clogging that can halt operations.

3. Precision Engineering for Extended Run Life

The FARR Plunger™ is engineered with precision tolerances that optimize its seal within the pump barrel. This minimizes fluid bypass, ensuring higher efficiency and maintaining consistent production rates. Additionally, the improved seal reduces friction, which translates into lower energy consumption and extended run life.

4. Performance Under Pressure

Field tests have demonstrated the FARR Plunger™’s ability to handle extreme pressure conditions without compromising performance. Even in high-pressure wells, where other plungers might struggle, the FARR Plunger™ remains reliable, offering operators peace of mind and a dependable solution for their most demanding wells.

Field Success Stories: Real-World Applications

Case Study 1: High-Sand Well in California

An operator in Kern County, California, faced constant downtime due to sand-laden wells causing frequent pump failures. After switching to the FARR Plunger™, the operator experienced a 70% reduction in well pulls over a six-month period, significantly improving production uptime and reducing maintenance costs.

Case Study 2: Harsh Conditions in the Permian Basin

In the Permian Basin, known for its extreme operating conditions, an oilfield operator implemented the FARR Plunger™ to combat high-pressure and abrasive environments. The result? Pump run times were extended by more than 200%, allowing for continuous production and lower operational costs.

Economic Benefits of the FARR Plunger™

Investing in the FARR Plunger™ provides tangible financial benefits for operators:

- Reduced Maintenance Costs: By minimizing wear and extending pump life, operators save on frequent replacements and labor costs associated with well pulls.

- Increased Uptime: With fewer interruptions, production can continue uninterrupted, maximizing revenue potential.

- Energy Efficiency: The optimized seal reduces energy consumption, contributing to lower operating expenses over time.

Designed for the Future of Oilfield Operations

The oil and gas industry is facing growing pressure to improve operational efficiency while minimizing environmental impact. The FARR Plunger™ aligns perfectly with these goals by:

- Enhancing Resource Utilization: Fewer replacements mean reduced material waste and a smaller carbon footprint.

- Supporting Sustainability Initiatives: Extended equipment life reduces the overall environmental impact of operations.

As the industry evolves, operators need tools and technologies that not only deliver performance but also support sustainable practices. The FARR Plunger™ is a prime example of how innovation can meet these dual objectives.

Conclusion

In a world where every operational decision impacts the bottom line, the FARR Plunger™ offers oilfield operators a clear path to greater efficiency, lower costs, and enhanced performance. Whether you’re dealing with high sand content, extreme pressures, or simply looking to improve your well’s run life, the FARR Plunger™ is a solution you can trust.

Ready to revolutionize your rod pump operations? Contact us today to learn more about the FARR Plunger™ or connect with me directly on LinkedIn at David Muth to discuss how we can help optimize your operations.

#OilfieldSolutions #FARRPlunger #MuthPump #WellOptimization #OilAndGasTech #Efficiency #SustainabilityInEnergy #WellPerformance