Your Trusted Technical Pump Experts – Delivering Solutions Beyond Expectations

THE BEST PLUNGER & THE BEST PUMPS

The Farr Plunger™ outperforms all others in the field. {BY FARR}

30+

3K+

60+

Far Fewer Well Pulls Equal FARR Less Risk

Reduce Downtime / Increase Profits

A longer lifespan is just the beginning. 50+ years of industry experience has allowed us to push performance engineering to a new benchmark. The FARR Plunger outperforms, outruns, and flat out saves you valuable time and hard-earned profit. It’s time to push industry inefficiencies aside and use the only plunger that will increase your pump run life by at least 200%.

Per 100 FARR Plunger Pump installs you save an average of $875,000 annually in well-pulling costs.

Increased pump life means increased profits. The FARR Plunger is just that good no matter how sandy the play. Our plunger is uniquely engineered to handle stroke after stroke without locking caused by sand production.

Over the course of a year, using FARR Plungers reduces the amount of Stuck Pump jobs by an average of 12 jobs per month. We will greatly increase your production time while reducing: unneeded downtime, personnel risks, and environmental impact. The FARR Plunger is the superior solution to decreasing your well’s OPEX (Operating Expense).

Why Our Customers Love Us

Experience

Muth Pump defines experience: The skill & knowledge gained by actually doing a thing over a great deal of time. To master a skill and gain great proficiency and competence.

Superior Quality

Quality comes in grades: Quality is acceptable to a bare minimum. Good Quality refers to reasonable acceptance and quality. Superior Quality is unequaled and in a class unto itself that others struggle to compare.

Dependability

Muth Pump consists of Men who reflect the character of this great company. Family Men, Patriots and Veterans. They have been and will always be there for their Family, Faith and Flag. You can bet they will always be there for their clients!

Our Products

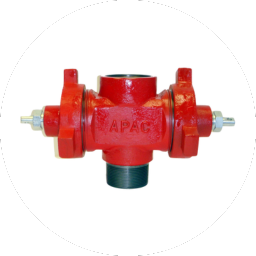

APAC 9000™

PCC TRAPPER

Lubricator

ROD LOAD CELL

Liquid Gauges

Threaded Ball Valves

APAC 9000™

The APAC 9000™ Series Blow Out Preventer (BOP) is an essential safety device designed to control well pressure and prevent blowouts during drilling operations.…With a full-opening design and the VERATON NS-500T steel-reinforced packing, this BOP offers durability and reliability in demanding environments. Key features include a quick and easy ACME cap thread for fast operation, eliminating the risk of cross-threading, and a blowout-proof ram screw for added security. Its compact design ensures easy handling while providing robust performance under high-pressure conditions.

APAC 9000™

APAC 9000™

The APAC 9000™ Series Blow Out Preventer (BOP) is an essential safety device designed to control well pressure and prevent blowouts during drilling operations.…With a full-opening design and the VERATON NS-500T steel-reinforced packing, this BOP offers durability and reliability in demanding environments. Key features include a quick and easy ACME cap thread for fast operation, eliminating the risk of cross-threading, and a blowout-proof ram screw for added security. Its compact design ensures easy handling while providing robust performance under high-pressure conditions.

At Muth Pump, we offer personalized, local service backed by decades of experience and innovative solutions that extend far beyond our region. Our unique products and expertise serve clients both locally and worldwide, ensuring that every operation benefits from our global reach and industry knowledge.

Testimonials

Ricky Huey - CDI - Freer Texas

Kyle A. Williams - President - Sutton Pump & Supply, Inc.

Jamie Griffin - Pump Shop Manager - Green Country Supply, Inc.